Wilhelm T & P is the right contact for consultation on systems in the textile and plastics processing industry. We have been working with leading international machine manufacturers for decades. This allows us to guarantee our customers the best quality and reliable service. We have been representing company Dietze+Schell successfully since 1985.

Since 1951, Dietze + Schell has been a reliable partner for the textile, plastic, and glass fiber industries. With system solutions and equipment, the clear goal is to meet the demands of customers, even the most demanding ones. Materials such as basalt, packaging tape, or artificial turf are processed, with each material having its own specific characteristics and therefore presenting particular challenges in winding or refining. Whether it is natural fiber or technical yarn, with or without sizing, web or fabric.

Technical yarns

Technical yarns, mostly made of polyamide, polyester or polyethylene, have a round cross-section and serve as raw material for various products such as silk fabrics, sack fabrics, harvest binding yarn, tires, mat fabrics, and many others.

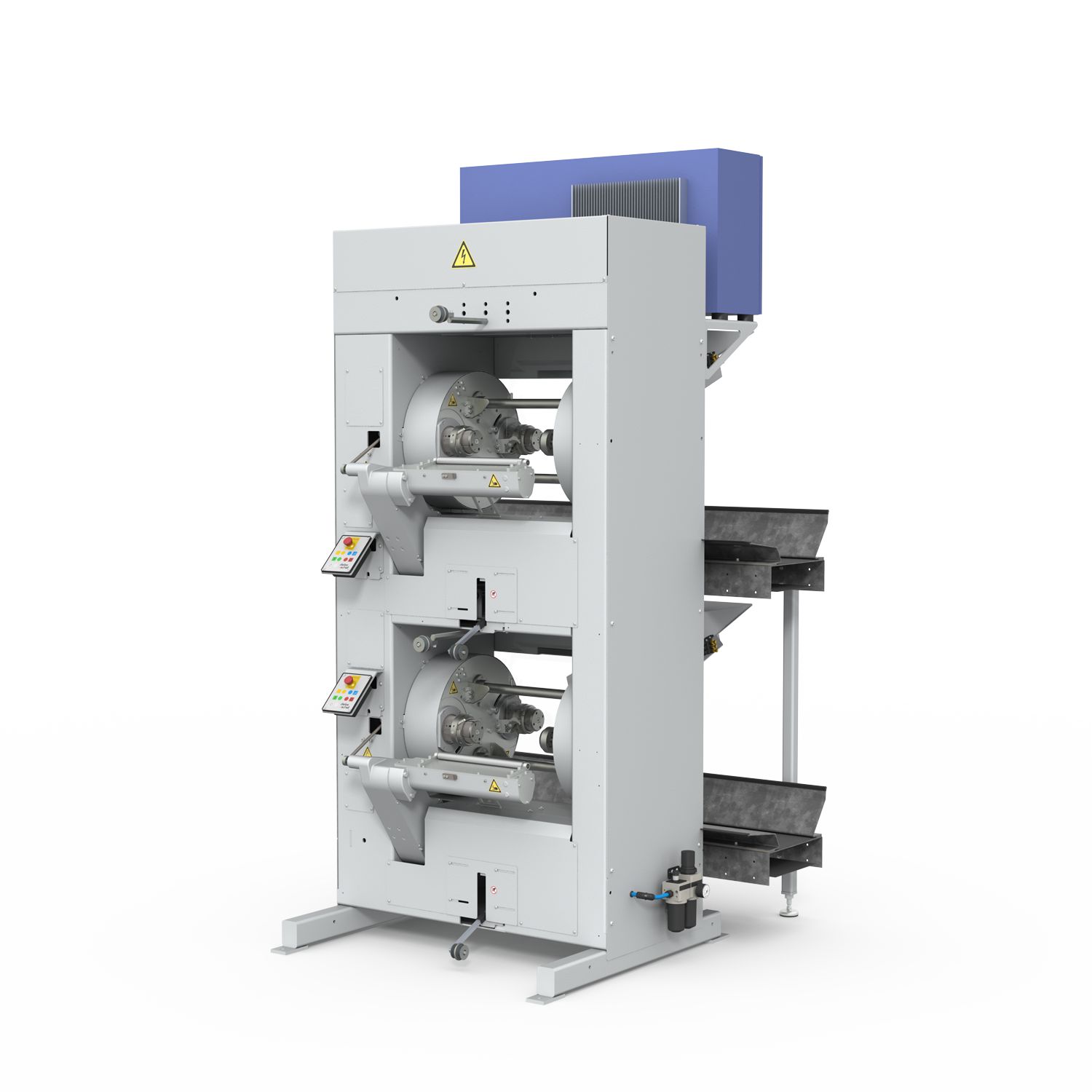

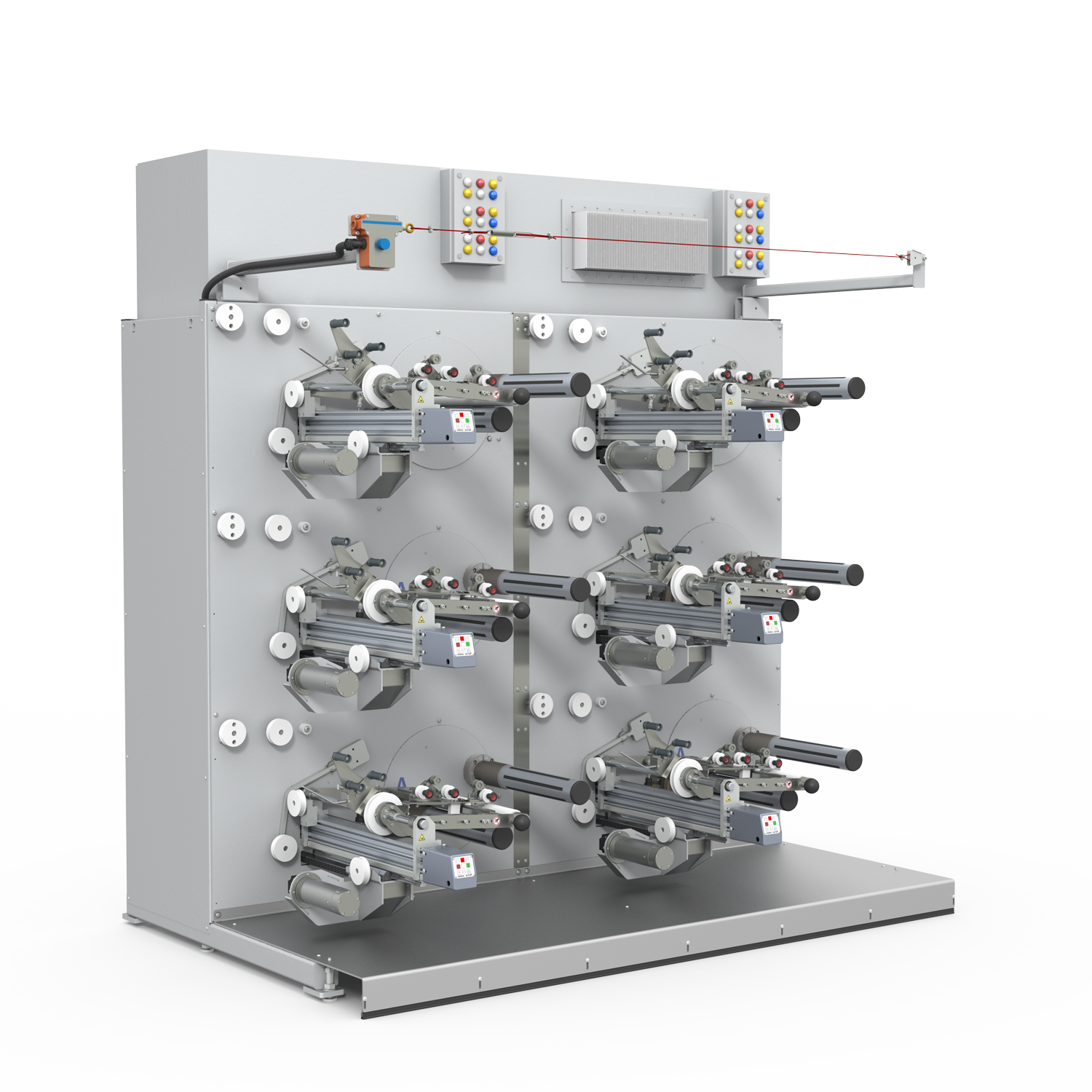

Dietze + Schell not only offers various winding and rewinding machines but also additional components to refine technical yarns. By using these machines between the production and winding process, various fluids can be applied to the yarn to improve its smoothness or increase acid resistance. Quality control is carried out through sensor systems that can detect thick and thin spots, knots, and other defects.

Glass fibre & basalt

The production of basalt and glass fibers is similar in their process and properties. However, the main difference is that basalt is a natural product, while glass fibers are artificially made and mainly consist of silicon and aluminum dioxide, magnesia, bromine trioxide, and calcium oxide.

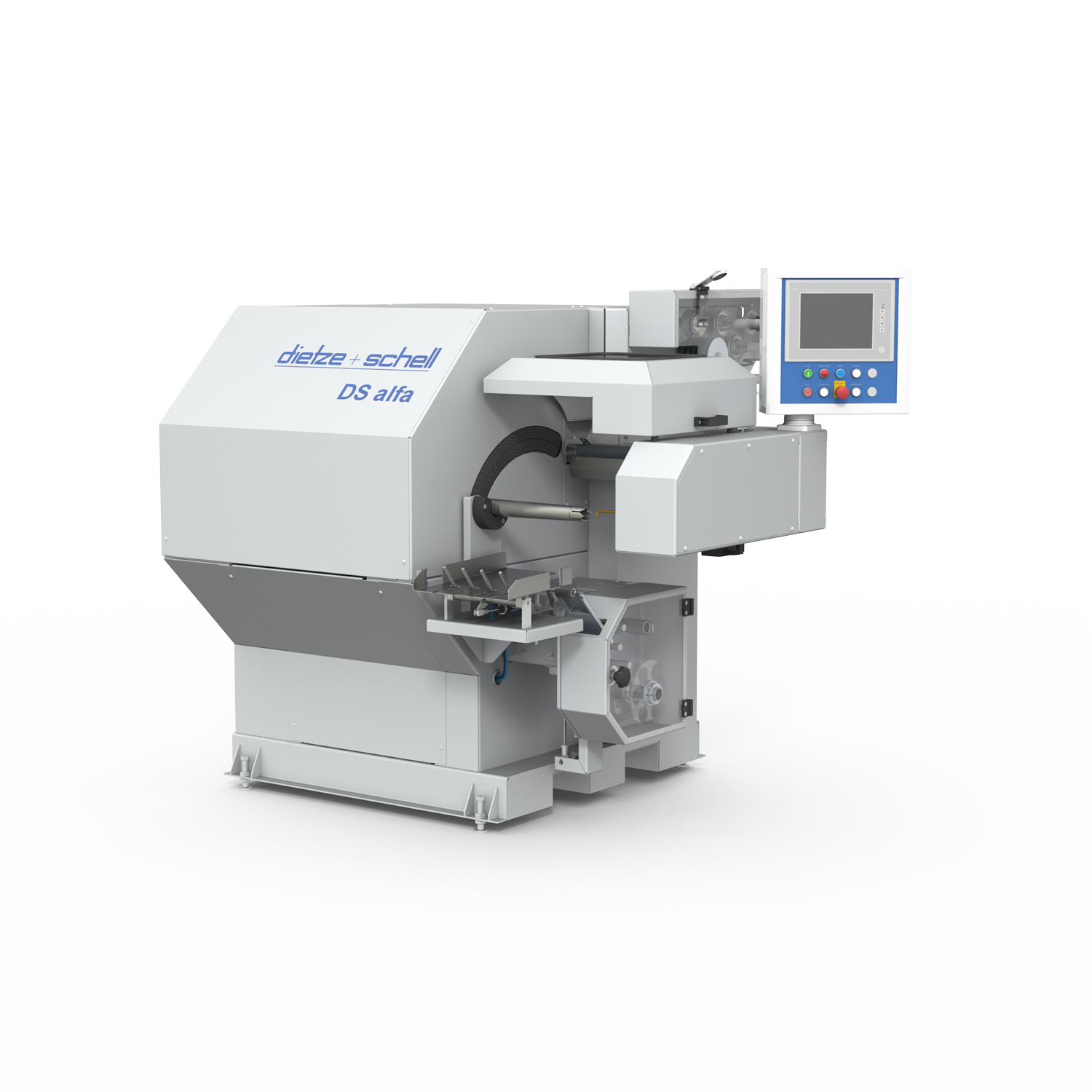

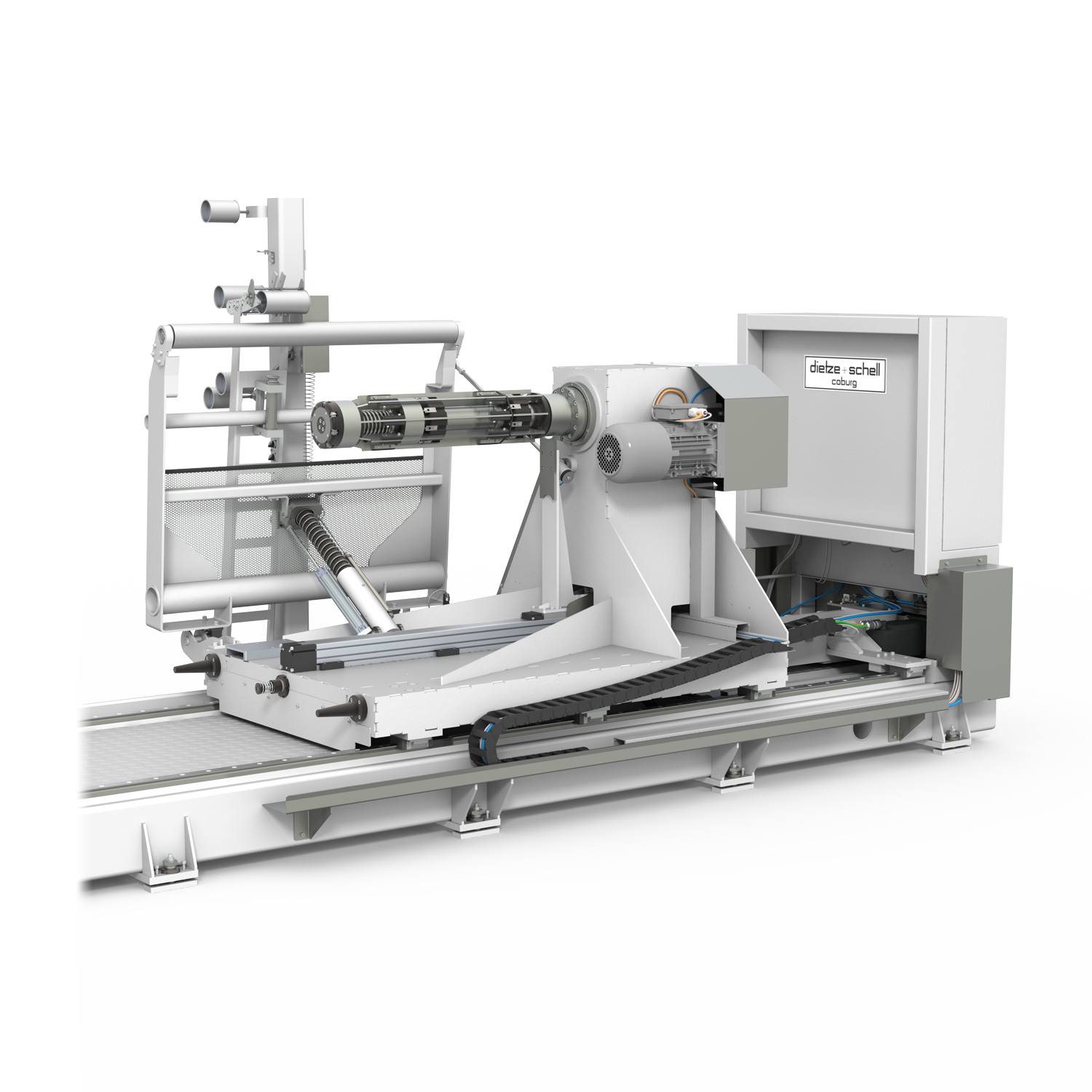

Basalt and glass fibers are drawn as the finest filaments from a melt. Dietze + Schell machines take up the fibers, mainly using Rover and inline choppers. While Rover winds up the material, choppers chop the fibers. The chopped fibers with a length of 3 to 50 millimeters are used for the production of glass fiber-reinforced plastics.

Adhesive tape, foam lane and film

The production of adhesive tapes, foam tapes, and films is done in a width of up to 1,000 millimeters and is then cut to size. The systems from Dietze+Schell take over the cutting process and wind the finished material onto spools in parallel or cross-winding. They process one-sided and double-sided adhesive as well as non-adhesive films, sheets, and tapes. The finished products are used in the fields of packaging, sealing, and thermal insulation.

Sima S.R.L., a subsidiary of Dietze+Schell in Italy, produces extrusion systems. The Dietze+Schell group is thus able to design and build complete extrusion lines for films.

Carbon

Dietze + Schell produces fully and partially automated winding systems specifically for rewinding carbon fibers, often performing finishing processes such as texturing and bulking. Since carbon fibers are electrically conductive and can cause shorts in electronics, the machines' electrical and electronic components are specially protected.

The machines allow for the mixing of carbon and plastic fibers into a homogeneous blend. Carbon fibers are often embedded in resin to produce prepreg mats. Dietze + Schell also supplies the appropriate machines for processing prepregs, such as unwinding, cutting, and rewinding. These materials are particularly used in the aerospace industry for lightweight construction.

Straps

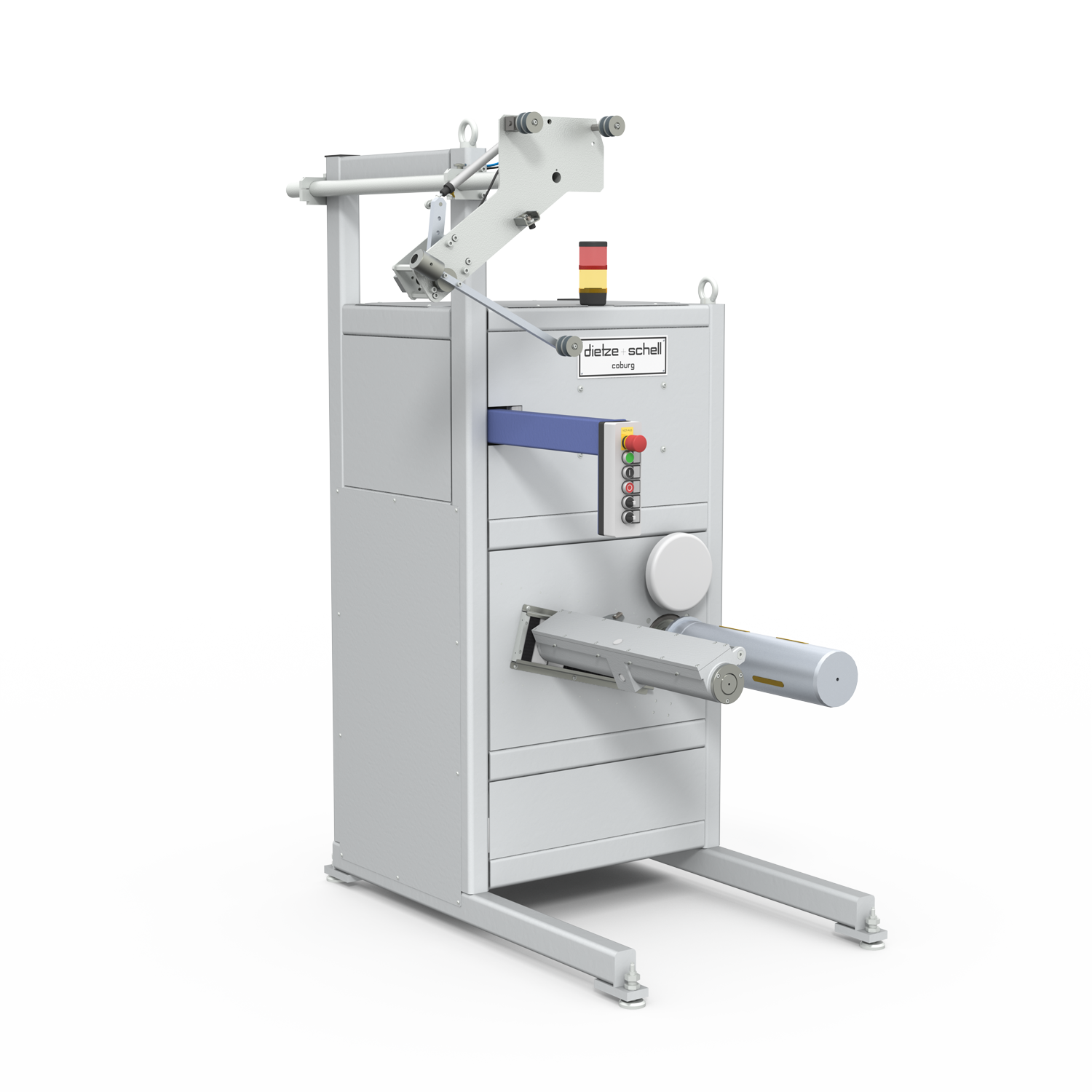

Dietze+Schell produces winding machines for various types of packaging tapes and for all package sizes. The machines are available in manual versions up to fully automatic machines for automatic spool change.

In addition, the Dietze+Schell group develops finishing machines, for example, to interlace plastic packaging tapes with paper strips, also known as "linear crimped paper". Plastic packaging tapes are either extruded and wound in exactly the width they will later be used, or they are produced on a wider web and later cut to the desired format. The first method offers a large price advantage, while the second produces particularly stable tapes that are hardly stretched even under high loads or strong stress.

Monofilaments

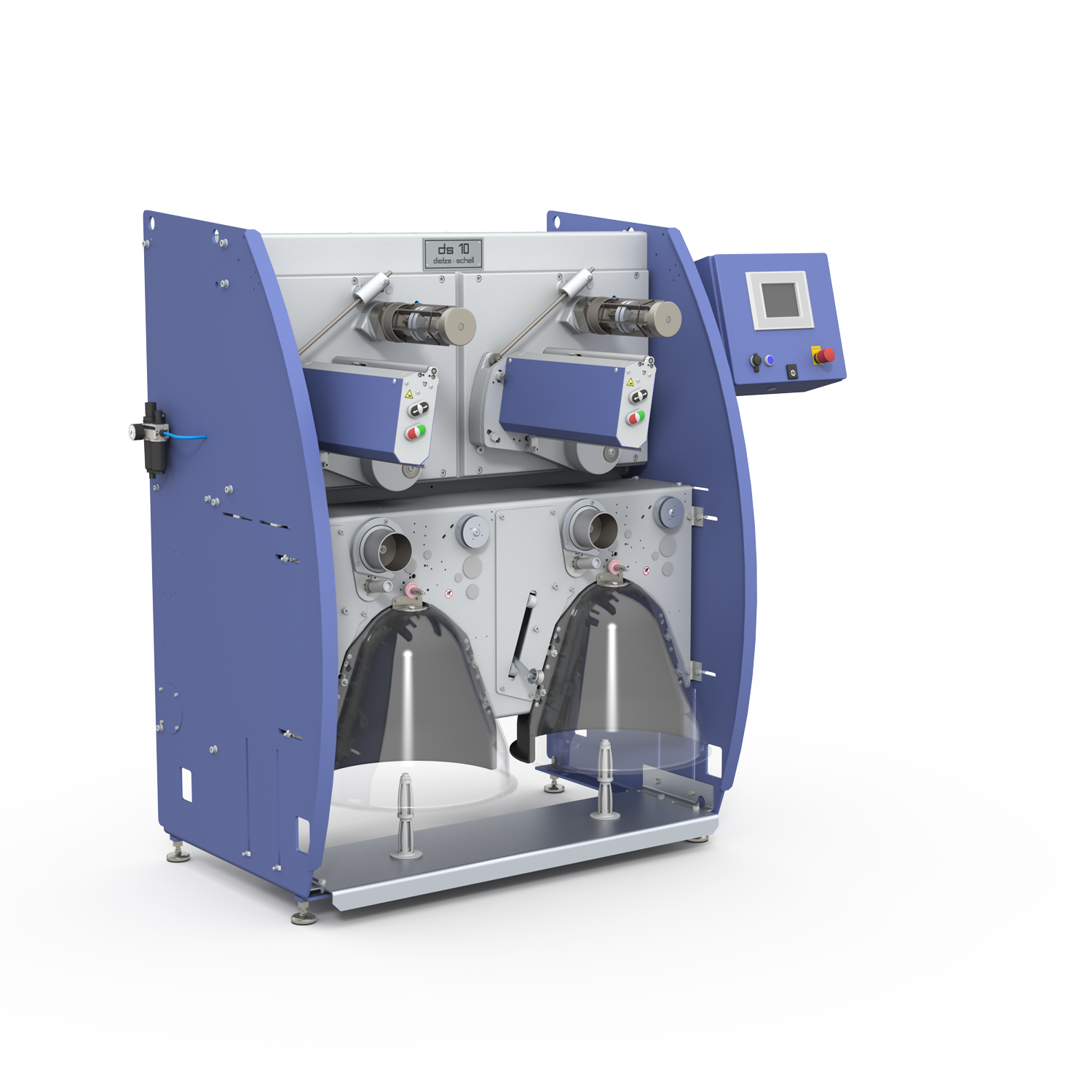

Dietze+Schell produces manual, semi-automatic and fully automatic winding systems for monofilaments and also offers quality testing components such as yarn thickness control. Monofilaments are round or flat-round fibers with a diameter ranging from 0.06 to 6 millimeters and differ from multifilaments in that they consist of individual fibers. These are used, for example, in the production of artificial turf.

Non-wovens

Dietze+Schell has a manufacturer of non-woven fiber materials in its group, Trima. The Czech Republic-based company produces mats up to 600 centimeters wide and winds them onto metal or plastic cores.

These mats made of natural, plastic, or glass fibers are used, among other things, for sound insulation and thermal insulation and typically find buyers in the automotive and construction industries. In addition, non-woven mats are also suitable for reinforcing plastics.